Case Study: Boosting Solar Panel Efficiency with Sparked Titanium Coatings

.png?width=50)

A team of researchers from Chiang Mai University in Thailand has developed an innovative coating that enhances the performance of solar panels—using high-purity titanium wires supplied by Advent Research Materials.

Their work, published in Scientific Reports, details a low-cost, scalable process that delivers three crucial benefits to photovoltaic (PV) systems: reduced reflection, improved self-cleaning properties, and increased power output.

The Challenge

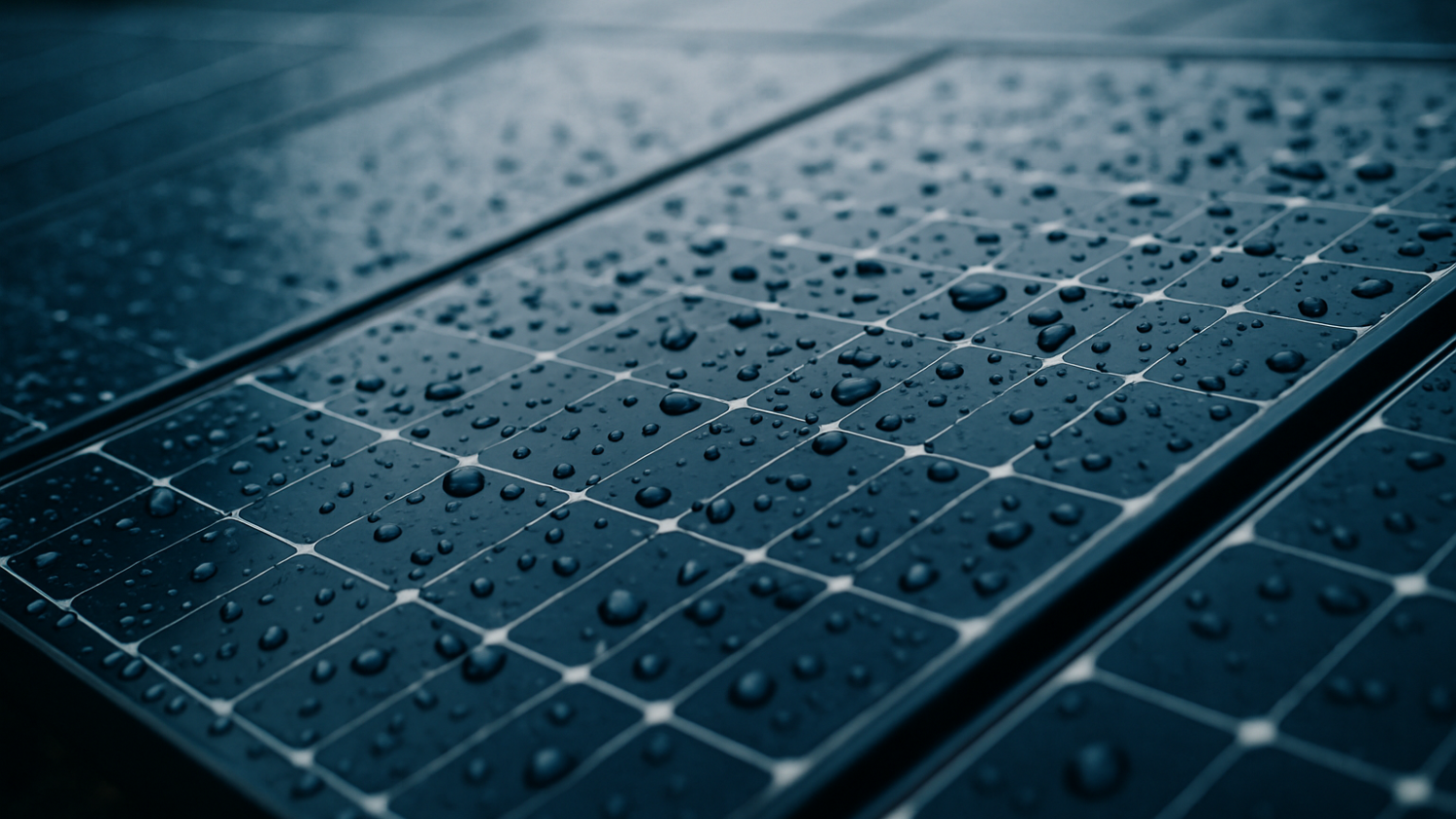

Soiling and light reflection are major contributors to reduced solar panel efficiency. Dust build-up and poor light absorption can significantly impact power generation, particularly in areas with frequent rainfall or airborne pollution.

The Solution

The research team used a technique known as the sparking process to create a nanoparticle-based coating from titanium wires (0.25 mm diameter, 99.5% purity, Advent Research Materials). This simple but highly effective method produces fluffy, porous TiO₂ films with three key characteristics:

- Antireflective properties that help trap more sunlight

- Superhydrophilicity that encourages water to spread and carry away dust

- Photocatalytic activity that breaks down organic contaminants on the panel surface

The result? A coating that boosts solar output—without expensive or resource-intensive manufacturing steps.

Real-World Testing

To assess long-term performance, the team installed coated and uncoated solar panels side-by-side in outdoor conditions over a 10-month period in Chiang Mai. The panels were monitored in real time via IoT-connected microcontrollers.

The findings were clear:

- The coated panels achieved an average power increase of 6.62%

- On cloudy days, the difference peaked at 14.22%

- The coating’s performance was most notable during the rainy season, when superhydrophilicity prevented muddy stains and improved light absorption

Advent's Role

Advent’s high-purity titanium wires played a critical part in the sparking process, serving as both the anode and cathode to generate the TiO₂ nanoparticle films. These wires were chosen for their quality and consistency—two attributes essential to ensuring uniform film formation and effective coating performance.

Why It Matters

This research shows how accessible materials and processes can lead to meaningful improvements in renewable energy output. The sparking method doesn’t require high-vacuum systems, chemical waste handling, or specialised facilities, making it suitable for scalable commercial application.

About Advent Research Materials

Advent supplies high-purity metals and materials trusted by scientists worldwide.

From early-stage experiments to real-world applications, our materials support research at the cutting edge of innovation.

Planning a new research project? Talk to us about your material needs.

Reference

Thongsuwan, W., Sroila, W., Kumpika, T., Kantarak, E., & Singjai, P. (2022). Antireflective, photocatalytic, and superhydrophilic coating prepared by facile sparking process for photovoltaic panels. Scientific Reports, 12, Article 1675. https://doi.org/10.1038/s41598-022-05733-7

Credit

Titanium wires (Ø 0.25 mm, 99.5% purity) used in the sparking process were supplied by Advent Research Materials Ltd.